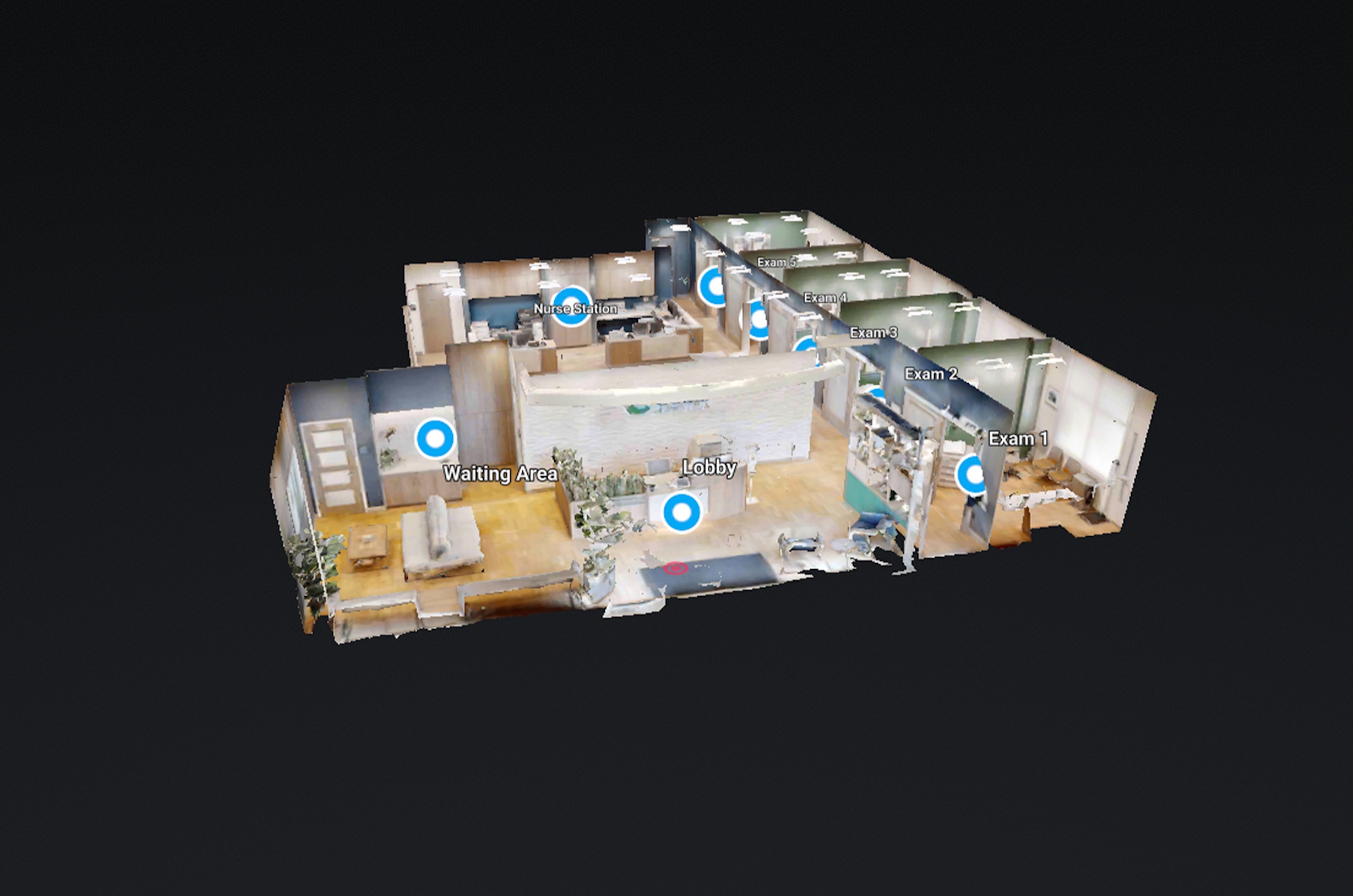

In the ever-evolving industrial sector, staying ahead of the curve is crucial. One technological advancement that’s changing the game for factories is Matterport 3D tours.

These immersive virtual tours offer a unique perspective on factory layouts and operations. In this blog, we delve into how Matterport 3D tours can revolutionize factory settings, offering insights and advice on their innovative applications.

- Enhanced Training and Safety Protocols: Matterport 3D tours can be a vital tool for training new staff. They provide a realistic view of the factory floor, machinery, and safety routes, reducing the learning curve and enhancing safety awareness without physically being on-site.

- Remote Monitoring and Maintenance Planning: With Matterport, factory managers can remotely monitor their facilities, plan maintenance activities, and identify potential issues before they escalate, all from a 3D model of their site.

- Streamlining Factory Layout Planning: Use Matterport 3D tours to experiment with different factory layouts virtually. This can optimize workflow and space utilization without the need for physical rearrangements.

- Enhancing Client Engagement and Transparency: Share 3D tours with clients to showcase your manufacturing processes and facility capabilities. This transparency can build trust and foster stronger business relationships.

- Emergency Preparedness and Response: Matterport 3D models can be invaluable for emergency preparedness, providing first responders with a detailed layout of the factory, which can be crucial during emergency situations.

- Sustainability and Energy Efficiency Audits: Use 3D tours to conduct virtual energy audits, identifying areas where energy efficiency can be improved, contributing to more sustainable factory operations.

Conclusion: Matterport 3D tours are not just a technological novelty; they are a transformative tool for factories. They enhance training, safety, efficiency, and client engagement, offering a comprehensive view of industrial spaces like never before. Embracing this technology means stepping into a future where factory management is more efficient, safe, and transparent.